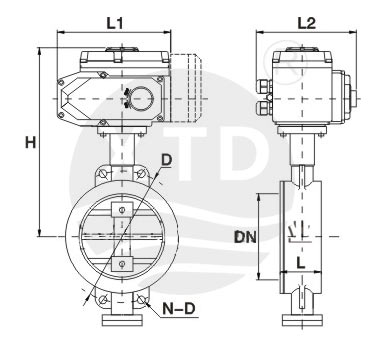

Nominal diameter: DN40 ~ 1000mm

Nominal pressure: PN0.6 ~ 1.6MPa

Main material: cast iron, carbon steel, stainless steel, alloy steel, etc

Driving mode: electric

Design and manufacturing standard: GB/T 12238-2008

Standard for structural length: GB/T 12221-2005

Connection flange standard: GB/T 9113

Pressure and temperature classification: GB/T 12224-2005

Test standard: GB/T 13927-2008

Application scope of desulfurization butterfly valve:

Can be widely used in water and electricity, sewage, construction, air conditioning, petroleum, chemical industry, food, medicine, light textile, paper, water supply and drainage and other fluid pipeline as regulation and closure use, and can be changed by the material, suitable for water, gas, oil and other different media, applicable temperature -20 ~ 80¡æ.By changing the valve plate seal ring, o-ring, butterfly plate, shaft and other materials, can be used for a variety of media and different temperatures.Valve automatic control is equipped with high quality electric actuator or double-acting pneumatic actuator, can achieve automatic and manual double opening and closing functions.

Structure features of desulfurization butterfly valve:

The main structure is composed of valve body, disc, seat, stem and drive operation mechanism, etc. The seat adopts detachable structure, and according to the physical and chemical characteristics of different media, choose the corresponding material of high temperature, low temperature, corrosion resistance, light resistance and aging resistance.

The inner and outer surfaces of valve ductile iron shell can be coated by high temperature electrostatic coating with epoxy resin powder. The coating has high corrosion resistance and high bonding strength with ductile iron matrix. The coating degree is 0.2-0.5mm.

1. No eccentricity design is adopted in the middle-line structure, which has the characteristic of low operating torque and remarkable economic efficiency when configuring the electric device;

2. Reasonable design, compact structure, simple installation and disassembly, easy maintenance;

3, the use of rubber liner structure, butterfly circular sealing surface precision processing to a higher finish, rubber seat friction coefficient is very low, the valve service life is long;

4. The flow characteristics of the sealing surface of the valve plate are linear, with small flow resistance coefficient and small valve flow resistance;

5, the unique design of molded rubber seat with excellent balance and support, effectively avoid the uneven force caused by the damage to the rubber, the valve at the full close position, rubber in the best compression state to maintain zero leakage;

6. The rubber sealing surface of the valve at two ends highlights the nodular cast iron flange surface, and the valve does not need additional rubber sealing gasket when installed in the pipeline

7, the butterfly valve operation mechanism choose flexible;

8, butterfly valve beautiful appearance good corrosion resistance.

Hotline:

Hotline:

+86 022-88527808

+86 022-88527808